Scale-up

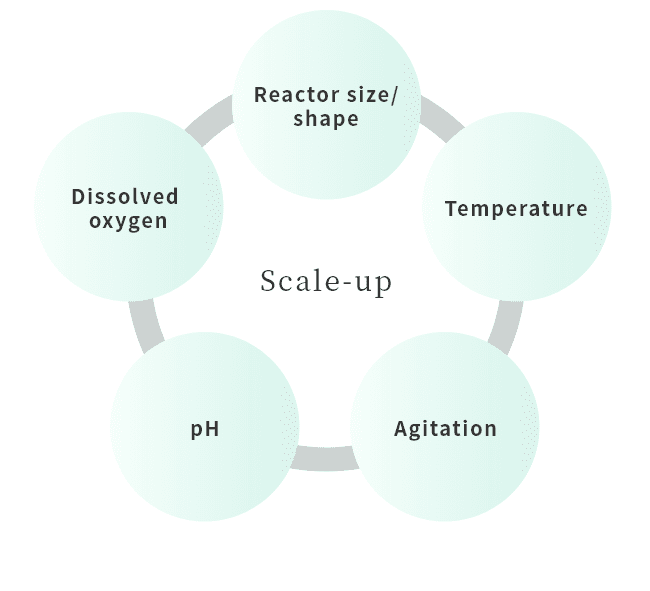

Scale-up Factors and Our Strengths in Bioreactors

When scaling up bioreactors used in microbial culture, control factors include dissolved oxygen concentration, pH, temperature, and agitation (blade shape/speed). For example, microorganisms that grow and produce substances under aerobic conditions require strict control of dissolved oxygen concentration, so we control and optimize agitation and aeration conditions during scale-up.

We have experience in many scale-up studies of bioproduction of aromatic compounds (especially phenols), and have accumulated expertise in handling genetically modified bacteria and the optimization of various culture conditions.

Scale-up study initiatives

We have a pilot plant (our largest culture tank is 500 L) at our Shizuoka Research Laboratory that we use to conduct scale-up studies on bioproduction.

By controlling environmental factors relating to culture, such as cultivation conditions and medium conditions, we aim to achieve the equivalent productivity as a laboratory, even in a scaled-up facility.

Through this initiative, we aim to clarify issues and optimal conditions for scale-up, and establish the design specifications necessary for the introduction of mass-scale facilities.

Pilot plant

500 L culture tank

Example Scale-Up Study

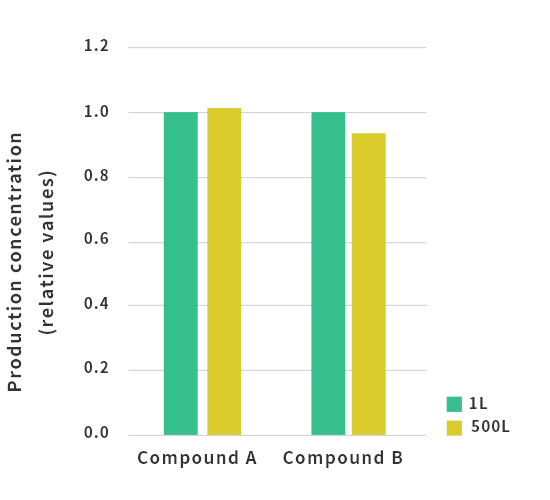

This figure shows an example of a scale-up study for two typical compounds.

By optimizing the culture and medium conditions from pre-culture to main culture, we have achieved a production concentration at the pilot scale (500 L) that is almost the same as at the lab scale (1 L).

The design specifications and expertise gained here can be applied to the further scale-up of facilities.