RITE Bioprocess

A unique bioprocess for highly efficient production

The "RITE Bioprocess" is a growth-arrested bioprocess. It is an innovative core technology that enables highly efficient production of biofuels (ethanol, butanol, etc.) and green chemicals (aromatic compounds, amino acids, organic acids, etc.) from various types of non-food biomass resources.

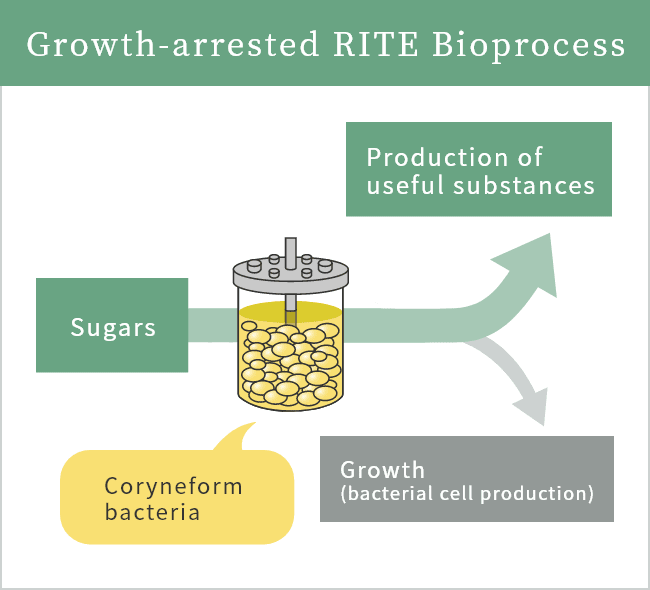

Microbial cells stopped their growth can be utilized as cell factories packed with enzyme catalysts. The various kinds of sugars added are not used for cell growth, but are instead used to produce useful substances. Unlike chemical production processes, this technology is environmentally friendly because it can be operated continuously and repeatedly under ambient temperature and mild pressure conditions, thereby reducing energy requirements.

This technology is increasingly paying attention both domestically and internationally as a necessary step to achieve carbon neutral.

A new development of the "RITE Bioprocess "

= "a growth-arrested bioprocess" that enables highly efficient production

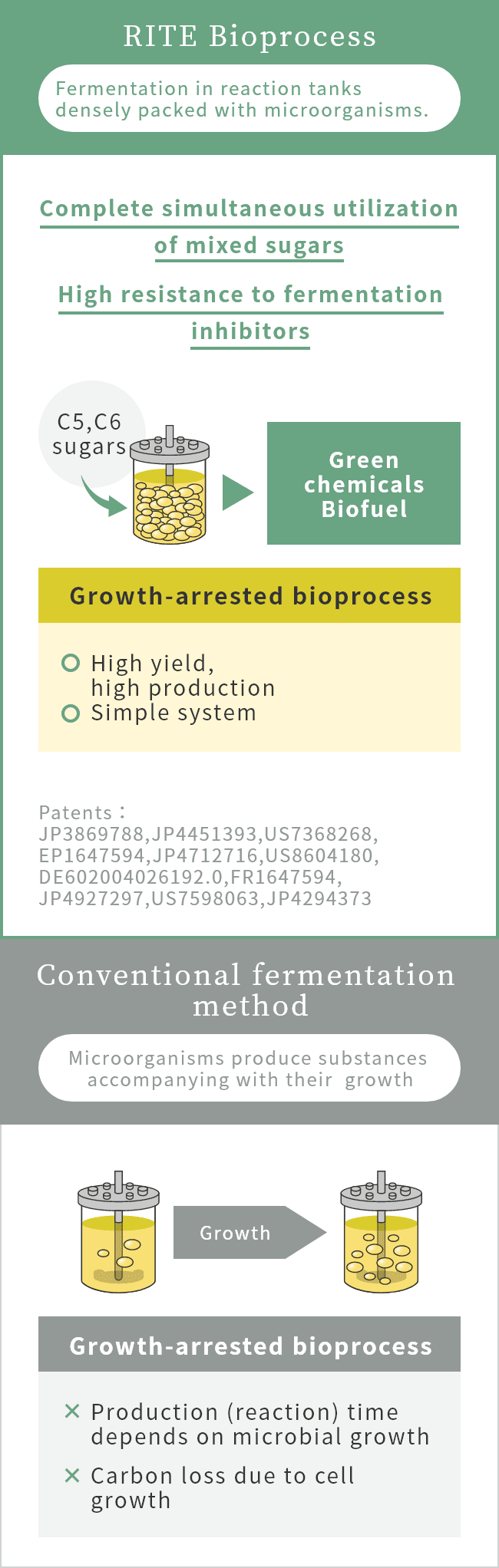

In conventional fermentation methods, sugars are used for both growth and production of the useful target substances. Therefore, the production yield from consumed sugars is low.

After large numbers of coryneform bacterial cells that are highly metabolically engineered to efficiently produce the target substance are densely packed into reaction vessels, the reactions are carried out under anaerobic conditions or in other states in which cell division ceases due to removing factors essential for growth, thereby arresting cell division. Because the nutrients and large amounts of energy required for normal growth are no longer needed, the sugars are not used for the cell growth, instead are utilized for the production of the target substance.

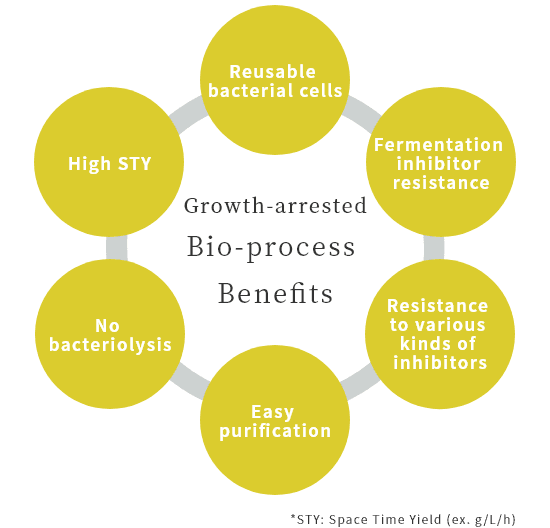

There are many other advantages, as shown in the figure, such as the ability to reuse bacterial cells and a resistance to both fermentation inhibitors along with a variety of other inhibitors.

In addition, the remarkable development of "smart cell" technology based on a combination of digital- and bio- technologies in recent years has made it possible to design novel artificial metabolic pathways and construct high-production strains in an extremely short period of time and in a more rational manner than was previously possible. This means that the technologies can be used to produce various types of chemicals at high yield that were previously considered impossible.

Simultaneous utilization of C5 & C6 sugars

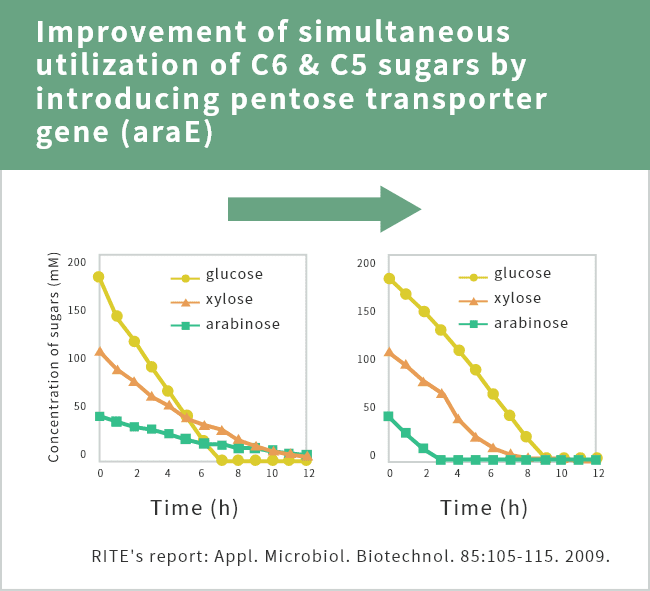

Cellulosic biomass is a type of non-food biomass consisting a mixture of C5 sugars, such as xylose and arabinose, and C6 sugars such as glucose. Therefore, the simultaneous utilization of C5 and C6 sugars is essential for the efficient production of cellulosic biomass as a feedstock.

Coryneform bacteria with C5 sugar metabolism genes utilize xylose (C5 sugar) and arabinose (C5 sugar) at a slower rate than glucose (C6 sugar). Thus, when raw materials are added continuously, only C5 sugars remain and accumulate, which results in a reduced compound production efficiency.

Using RITE technology, we have succeeded in increasing the utilization rate of C5-sugars to that of C6-sugars by introducing additional C5-sugar transporter genes. This allows for the complete simultaneous use of C5&C6 sugars and efficient use of cellulosic raw materials. In addition to this, oligosaccharides derived from various biomass feedstocks are also made available.

High resistance to fermentation inhibitors

Many types of non-food biomass require chemical or enzymatic treatment to turn them into sugars usable by microorganisms.

Fermentation inhibitors such as phenols and furans generated by pretreatment of lignocellulosic biomass are known to strongly inhibit the fermentation process of target substances and are a major obstacle to bioproduction.

Therefore, it is essential to increase the resistance of microorganisms (bacteria) to fermentation inhibitors to enable the efficient production of target substances. The "RITE Bioprocess" is a growth-arrested production process that is highly resistant to fermentation inhibitors, enabling high efficiency and enhanced production.