GCC's Goals

Contributing to carbon neutral by 2050

Green Chemicals Co., Ltd.(GCC), has been developing technologies to produce various chemicals that are conventionally produced from oil-based raw materials. We use the RITE Bioprocess to produce useful substances from non-food plant-derived materials as feedstock.

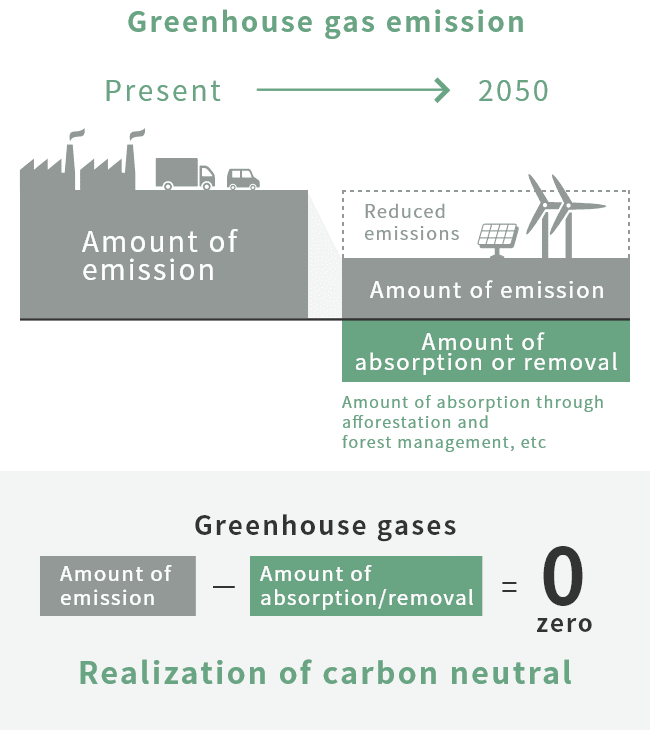

Since the government of Japan declared that Japan would realize carbon neutral by 2050 in October 2020, "carbon neutral" has been taking more attention than ever before.

The term "carbon neutral" means that "the amount of emission" minus "the amount of absorption through afforestation and forest management, etc" and "the amount removed by burying the gases underground" must be balanced out exactly. Our technology is one of an extremely effective way to switch from petroleum-derived products to plant-derived products.

We hope to play a major role in achieving carbon neutral by 2050 through the commercialization of our technologies.

Fermentation and genetic recombination technology

Since ancient times, people have used natural microorganisms to produce various products such as alcohol, cheese, soy sauce, and miso through fermentation. The RITE Bioprocess that we use is an advanced form of the traditional fermentation process.

We can design artificial metabolic pathways, and applying genetic recombination technology, we can modify the pathways of the microorganisms to create strains optimized for the production of target chemicals. We are constantly working to improve their functionality for higher productivity and yield.

Making active use of non-food biomass resources

We are making active use of non-food biomass resources. One of the candidate feedstocks we are focusing on is the squeezed residue (extra-liquid fractions) of orange juice lees.

Although the solid lees are used as compost and cattle feed, the liquid fractions are disposed as industrial waste. Their effective use is highly beneficial. This kind of effective use of food waste is also essential for bioeconomy.

In 2020, we began to study for utilizing the squeezed residue (extra-liquid fractions) of orange juice lees, and we have succeeded in achieving productivity equivalent to that of the glucose, a conventional feedstocks often used for industrial fermentation.

Learn more about Green Chemicals

-

Green Chemicals Production Technology

This section introduces Green Chemicals production technology, which produces a variety of useful compounds derived from non-food biomasses at the world's highest level of production.

-

Developed products lineup

Green Chemicals has realized the world's highest level of productivity through product development in areas such as 4-hydroxybenzoic acid, protocatechuic acid, shikimic acid, and phenol.